Logistic management for product storage usually is done through pallets, to be handled with flexibility. Also, innovative and productive goods of the market that allows palletizing are the robotic palletizer systems.

Logistic management for product storage usually is done through pallets, to be handled with flexibility. Also, innovative and productive goods of the market that allows palletizing are the robotic palletizer systems.

What is the robotic palletizer?

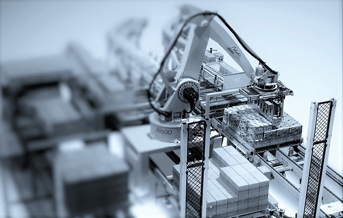

A robotic palletizer system is a group of machines (robots) built and designed to automatically place boxes with products on pallets, generally made of wood or plastic. Allowing the pallet to be the management unit , that can weigh up to 3 Ton.

The robot has great flexibility because it can handle different kind of products. In addition, it is easily programmable to build platforms with different sizes, in different types of arrangements and different types of pallets.

Within the fundamental parts of the robotic palletizer system are the following:

induction Conveyor in lines of entrance: in the feeding stage, the type of arrangement is determined. Some of the options are: the robot is fed 2 by 2 boxes, 3 by 3 boxes, or take a layer (full layer of boxes to place it directly on the robotic arm).

Empty pallets feeding: by means of a stacker, it administrates the pallets on a conveyor that will handle them. In that point, robot will take the product to place it according to the arrangement, capacity and height, as determined, in order to seize the volume of the trailer.

What is the basic care that the robotic palletizer needs?

Safety. Due to international standards, every robotic cell must have safety curtains that inhibit a person from entering to the robot area and get injured. These systems have the capability to detect if someone is there and automatically stop the operation.

Advantages of working with a robotic palletizer system

- Full quality control on the pallet and its position

- Flexibility to manage different kind of products, SKUs and references in the same cell. It is very easy to increase another product and another type of mooring pattern inside the platform.

- Safety during the whole operation process.

- Productivity allows an almost immediate return of investment.

- Quality of chosen arrangement is high and uniform.

- Brings you high reliability during operation.

This technology is used in different kinds of industries, such as food and beverages, personal care, pharma. Normally where the industry needs constant evolution of its products.

A bad intralogistics decision could bring some crises to your operation. Let us know your working system and find out together the best automated implementation that will give you productivity, reliability and quality.

Contact us and find out why we are the best intralogistics alternative in Mexico and Latin America!