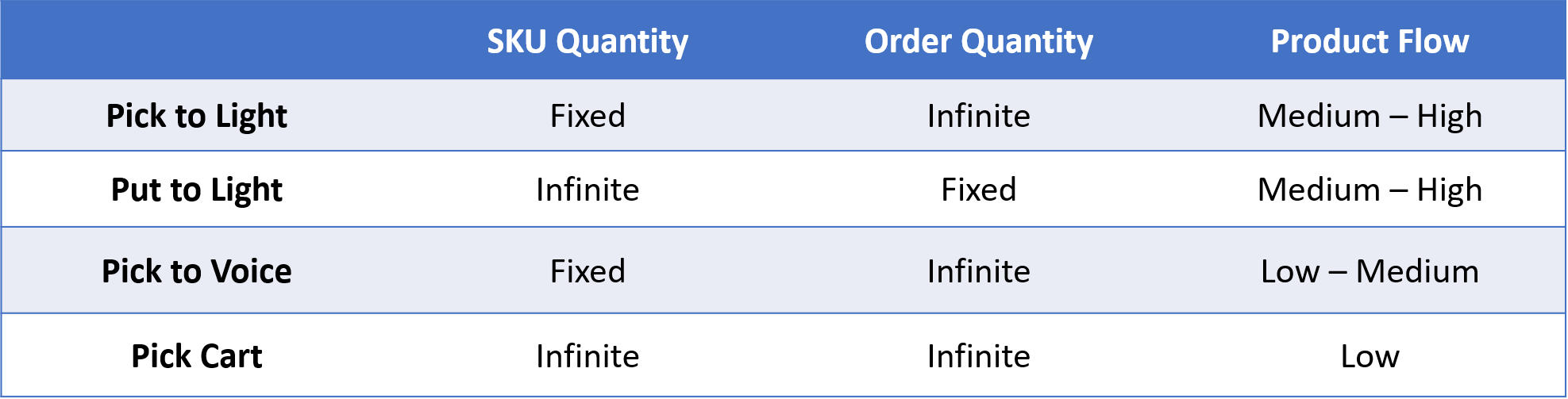

What’s the difference between Pick to Light, Put to Light, Pick to Voice and Pick Cart?

What’s the difference between Pick to Light, Put to Light, Pick to Voice and Pick Cart?

The distribution center is one of the strategic areas in most companies since different processes are added here that add value such as the assortment of orders to the different retail stores, to own stores or even to the final customer.

Thus, the distribution center has the objective of supplying its customers so that in the end there is a product distribution as quickly as possible. This is why there is a constant need to increase productivity, reduction and costs, improve precision and quality in the order assortment. All this can certainly be achieved through different technologies such as picking technologies.

This type of semi-automatic technologies help the operator to carry out the picking tasks in a more redirected way, since these allow guiding the operator and people within the distribution center to make the assortment more efficient because the assortment lists are eliminated and therefore, human errors.

In addition to this, you can work together with software, either WMS or ERP. These control software are responsible for sending orders to the areas that will best consolidate those orders.

This software has been developed specifically for this type of process, which allows us to be a link that not only supports, it also allows multiple assortment applications for different industries, with the efficiencies you are looking for.

Some industries that benefit from this technology are:

The Put to Light system provides inventory control that allows you to update your inventory in real time, in addition to identifying how much time is left to complete with respect to the productivity that the control system is handling.

How does the Put to Light solution work?

Like the Pick to Light, the Put to Light works through light. The order is registered, so that an assortment order is linked to each light display. When the products arrive at the corresponding assortment zone, the barcode they bring with them is read, causing the displays corresponding to the products of the order to be illuminated.

Benefits of Put To Light

This solution allows you an assortment of orders concentrated in a single software in addition to eliminating problems in your processes through the accuracy they offer, decreasing the return rates, errors and allows identifying and correcting the causes when they occur.

They also help you keep the statistics of each product and facilitate the refilling through the automations that this type of solutions gives you.

Which industries does Pick to Light serve?

The Put to Light is ideal for companies that have their business heart in the assortment of orders in the industries:

Advantages of Pick and Put to Light systems

Both Pick and Light and Put to Light systems have advantages such as:

How does the Pick to Voice solution work?

Unlike the other two systems, the Pick to Voice is operated by a radio frequency terminal that has headphones with an integrated microphone, where they receive instructions via voice.

When registering the user in the system, it indicates the position (aisle and depth) where it has to go within the assortment area. The operator receives the instructions of the quantity and the SKU's that must be supplied to take them and place them on a platform. Once the order is completed, the quantity of assorted products is confirmed to continue with the process.

The Pick to Voice uses two-way communication with the order management system, portable and rugged terminal, hands-free - thanks to the work headband, real-time communications systems and more.

Benefits of Pick To Voice

Thus, the Pick to Voice offers a dynamic workflow, you can achieve greater productivity by operators, reduce errors and institutionalize your operation, making it ideal especially for distribution centers where it facilitates the process of order assortment, ideal for densities Medium to low.

These are some advantages of the implementation of Pick to Voice:

Which industries does Pick to Voice serve?

This is why this solution is ideal for different industries:

The Pick Cart is defined as a hybrid between or that can be Pick to Light to the Pick to Voice, since what this gives you is the possibility of having multiple orders that you can fill simultaneously.

How does the Pick Cart solution work?

This works through a car with multiple lights, which indicate the number of pieces to take from each shelf in a specific position. These alphanumeric displays indicate in which orders the products have to be placed and the quantity to be filled in the car.

This process is repeated until the assortment orders in the different zones are completed.

Thanks to its hybrid technology, it allows you to increase productivity because you are making assortment of consolidated orders, so it is ideal when there is a high number of SKUs to be stocked in several orders.

What industries is the Pick Cart used for?

Thanks to all these benefits offered by the system, it is ideal for industries that develop within e-Commerce thanks to the effectiveness that processes acquire and the speed in which orders are filled.

Pick Cart Benefits

The advantages of the Pick Cart system are the following:

These are the characteristics of each of the Picking technologies. We see how their implementation manages to offer you security, speed, order accuracy and more.

In the same way, the Return on Investment that you get with the implementation of picking technologies helps you to:

Don't wait any longer, implement the picking technology that best suits your needs as soon as possible. In G.I.Eicom we have the best solutions and experts who have the necessary knowledge to tell you which are the technologies that will give you the most benefit in your processes.

.png)

Contáctanos

Tlalnepantla, Edo. de Mexico.

Nuestras Ubicaciones

Edo de México

Querétaro | Guadalajara

Monterrey | Chihuahua