A conveyor system in the finished products area of different industries such as: food & beverage, personal care, cosmetics, among others; has to be flexible for handling products in boxes or pallets. In order to do so, there are different equipment for each of these needs.

Therefore, we are going to explain how each of them works along with some of their benefits:

Conveyor system for boxes’ handling

When it comes to operation where handling boxes is needed, equipment like zero-pressure accumulation, minimum-pressure accumulation, with intersection and even a sortation area can be used. When conveyors assemble together like meccano, they provide multiple advantages, such as:

- Space savings.

- Higher rate.

- Continuous rate due to a non-stop operation.

- Energy consumption is reduced because a good design will always use low-power motors.

- Different simultaneous actions, such as: moving, lifting or dropping down heavy boxes.

- Reduces operational costs.

- Order and productivity.

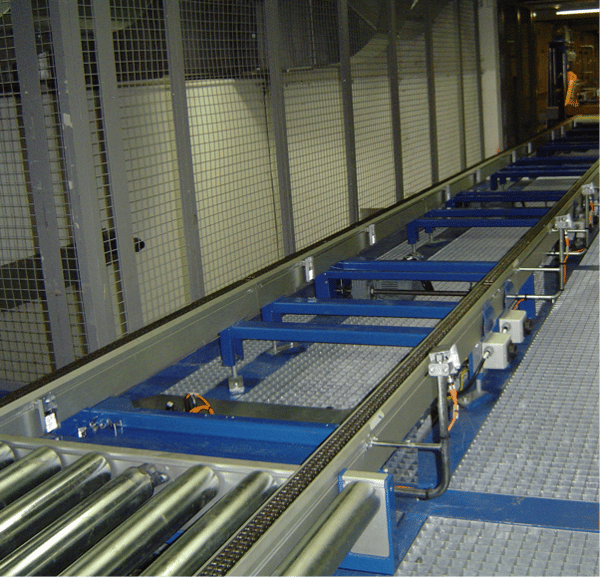

Conveyor system for pallets handling

Regarding pallets handling, when conveyors deliver the products to palletizing area, a full pile is made upon a wooden or plastic platform which can often weight up to two tons and sometimes it has to be moved to other areas where a forklift or a stacker crane will take it; this is the reason why conveyors for pallets are used. These systems can include several equipment, such as: zero-pressure conveyors, transference conveyors, turntable or rotating conveyor. The selection between them will depend on the required needs.

These are just some of the benefit of these equipment:

- Space saving.

- Higher safety.

- Reduction or elimination of waste.

- Rationalization and order in operations.

- Reduction of costs.

- Productivity improvement.

By analyzing your processes’ logic, the best intralogistics distribution of flow will be determined along with the appropriate equipment selection in order to have harmonious, productive and effective flows. During these processes, different kind of conveyors, controls and software will be implemented for a safety deviation, combination, transference and accumulation of pallets.

Choose innovation, choose GIEICOM due to its excellence in engineering, equipment and processes that guarantee results from the very first day of implementation. Here in GIEICOM, we are continuously working on offering the safest design in the market that also results in a quick Return of Investment.

Make an appointment today to increase your productivity right away!