Mexico is one of the main manufacturing countries in the world and that can be further strengthened by the investments that are being made thanks to Nearshoring. We see this reflected in the investments that were made in 2022, were manufacturers of refrigerators, washing machines, air conditioners, and household appliances invested more than 1.150 billion dollars in Mexico.

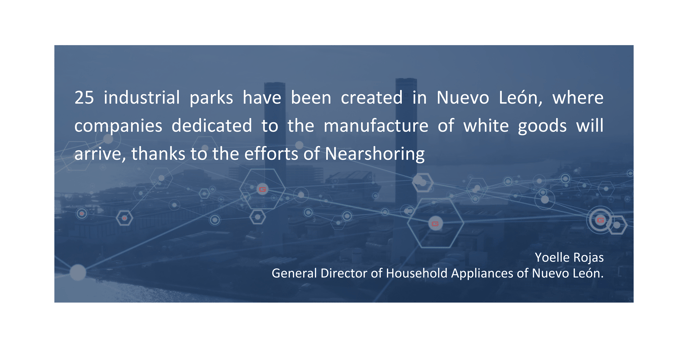

Nearshoring will be able to increase the production of household appliances by 8%. To give an idea of the importance of this industry in the country, you should know that Mexico stands out in the gross production of household appliances, which is around 14.8 billion dollars and which positions the country in fifth place as a global producer of household appliances.

However, it is important to project growth and opportunities, if we are not strengthened with the necessary infrastructure, it is possible that we block growth and improvement in our development; from design, manufacturing and the entire material flow process that it entails, to its distribution. Let´s analyze in this blog the scope for said industry and how it should be prepared.

What challenges does the home appliance industry face?

The home appliance industry is growing, but to maintain this leadership it must face challenges that will strengthen it. Among the most relevant we find:

● Higher competition: By having more investments in the country and larger suppliers in the industry, the competition will be greater.

It might seem like a simple issue, where if you know how to position yourself commercially you could & quot; capture the market", but the reality goes much further. In today´s competition, you must improve not only your production processes, but also storage and delivery times, to stay competitive and relevant in the industry.

You know better than anyone that the client does not forgive, that immediacy and quality have their golden stage, and there is no negotiation with said benefits.

● Technology Investments: Manual processes have a mysticism that is preserved by many businessmen, we do not deny that traditional processes entail a greater effort, however, for the current market they are obsolete.

To maintain the competitiveness of the national industry, it is necessary to invest in technology that allows improving productivity, as well as automating storage and material handling processes, with the aim of reducing delivery times.

● Volatility in raw material prices: This year will not be as complex as the years of the Pandemic, where the supply chains were broken, but given the volatility created by the war, and that a large part of the semiconductors still comes from China, it will be necessary to have very accurate planning and necessary to avoid being affected and scarce of resources.

Yes, the issue of material flow can be a headache

In order to optimize the flow of materials in a sustainable and efficient way, it is imperative to carry out an exhaustive analysis of the current operation, and of the scalability that we want to achieve. Such an analysis should integrate the transportation and storage processes, to identify any shortfalls in the flow of materials and rectify them through appropriate measures, with the aim of increasing efficiency.

At G.I.Ecom we are not only experts in offering cutting-edge technological solutions for your warehouses and production processes, we have a wide range of services that range from manual solutions to fully automated solutions managed by a WMS, which allows you to have information in real time to improve decision making.

You do not have to live this automated immersion alone, tell us about your project and let us advise you, more than 35 years in the industry have provided us with unsurpassed expertise.

Leave us your information here, we will contact you.