- Home

- Products

- Solutions

- Industries

- Software

- Services

- Blog

- Contact

Customer satisfaction

Given this situation and the growing complexity of the market, today more than ever it is essential to evaluate the effectiveness of this process, to ensure that optimal levels of productivity are maintained and any type of lag against the competition is avoided.

One way to verify that your DC order preparation is being effective is by analyzing the following:

To streamline the assortment processes, it is always important to verify that SKUs with greater movement or rotation are located in more accessible positions than those with low rotation.

Likewise, it is essential to verify that the products are classified by:

Typology

Amount stored

Turnover level

In this way, in the event that the arrangement of the SKUs does not meet these criteria, it is advisable to carry out a rearrangement and classification, so that operators can optimize their picking times.

|

*G.I.Eicom Tip: |

The Gold Zone is rated as the ideal zone to place SKUs in the storage area, as it reduces the risk of injury and significantly increases the productivity of the assortment by preventing operators from bending over or grabbing products overhead.

Area between operator's knees and shoulders.

|

It is important to note that if you have very heavy SKUs or that require special handling, additionally, you must have the appropriate tools for proper handling. |

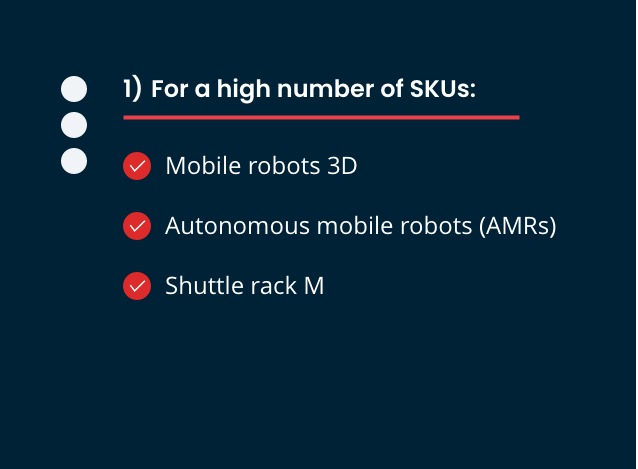

Despite being a fundamental element, many companies ignore the importance of the fact that picking and storage technologies fit perfectly with the profile of the SKUs, as well as with the type of process specific to each logistics strategy.

When everything is coupled, operators find and collect SKUs in a much more efficient way. In fact, it is proven that an automated picking environment with these features can increase pick-time productivity by up to 76%.

In order to have defined and orderly processes, and to achieve a level of logistical excellence in the assortment of orders, it is important that your Distribution Center has a well-established picking strategy. The most prominent are:

| Batch picking: It consists of registering, selecting, and filling more than one order at the same time. | |

| Zone picking: When the warehouse is divided into multiple zones and operators are assigned to fulfill the order fulfillment in a single determined zone. | |

| Pick and pass: When orders are transferred from one zone to another until their complete consolidation to be ready for shipment. | |

| Consolidación: It is normally used in conjunction with a “zone picking” strategy. Here, each zone simultaneously collects the SKUs required for an order and they are sent to a specific consolidation zone, and then proceed to their respective shipment. |

Finally, it is essential to maintain a constant analysis of all your assortment processes, in order to detect any area of opportunity in time and thus facilitate the search for alternatives to increase productivity in each one.

In addition to all the above, of course, it is also important not to forget monitor the KPIs associated with your order fulfillment, such as:

![]() Lead time

Lead time

![]() Optimal Stock

Optimal Stock

![]() Duration of order picking

Duration of order picking

![]() Number of orders packed and shipped by operator

Number of orders packed and shipped by operator

![]() On-time shipping rate

On-time shipping rate

![]() Storage cost per product

Storage cost per product

![]() % of products in reverse logistics

% of products in reverse logistics

Etc.

Does your volume of orders make it difficult to stock products? Find out how to fix it.

3 signs that your order fulfillment process needs optimization.

Has your order assortment increased in volume and complexity? Learn about the solutions that help us optimize.

Tips for proper fulfillment control

Given the accelerated technological evolution and the multiple challenges generated by the COVID-19 pandemic, today more than ever the immense need to automate the processes related to order preparation has been detonated, in order to maintain a high degree of competitiveness and successfully meet the demands of consumers.

However, despite the great benefits that order assortment automation brings, we find that some companies often hesitate to invest in this type of technology, due to certain myths that frequently revolve around this issue.

The most common are usually:

Although it is true that, in general, at a higher level of automation, you can obtain a Distribution Center with greater vanguard and productivity, the reality is that each DC is different and, therefore, has particular needs.

Therefore, it may not be necessary for all of your Distribution Centers to be fully automated. You can start semi-automating your assortment processes with various picking technologies, which can range from amazingly simple to very sophisticated depending on convenience, and still achieve significant productivity improvements.

On many occasions, automation projects may seem very time-consuming due to the number of factors that must be considered, such as: the creation of the design concept, the selection of the technology that best suits the needs and operations of the DC, the development of simulations and planning of the start-up, etc.

However, when you have the technical advice of a provider specialized in this type of solution, the automation project can be developed and implemented in incredibly attractive periods of time.

Of course, each project has its own peculiarities that make it simpler or more complex, but it is the level of expertise of your supplier that will make this process an agile and successful process.

This premise is not necessarily true. The automation of processes does not always imply the dismissal of employees or generate additional costs for their training.

It is important to remember that, depending on the objectives to be achieved, the type of technologies to be implemented and the business strategy, the results will be obtained.

What is a fact is that the rate of human error in operations is minimized, achieving a high level of safety and productivity thanks to the ergonomics of the facilities and the simplification of processes that automation technologies provide?

If the automated system is designed and implemented correctly, far from causing a loss of control in the processes, automation will help you eliminate many problems that are normally generated when management is carried out manually. In addition, it becomes an excellent ally as the volume of operations increases.

Finally, although it is true that the initial investment may seem a bit high, when you compare it with the benefits obtained, the reality is that the return on investment (ROI) of your automation project can have remarkably interesting rates.

However, for this, a lot also has to do with the experience of your provider. Hence the importance of looking for a specialist in the intralogistics solutions sector, who has a long-proven track record and a robust local support system.

From intelligent management software to the most sophisticated robotic solutions, technologies for automating order picking offer valuable advantages in terms of:

| Profitability | |

| Maximizing the use of space | |

| Precise inventory control in real time | |

| Continuity of the operation | |

| Safety when handling products |

| Working conditions for operators (fewer accidents) | |

| Delivery times and precision | |

| Continuous improvement of the customer experience | |

| Among others |

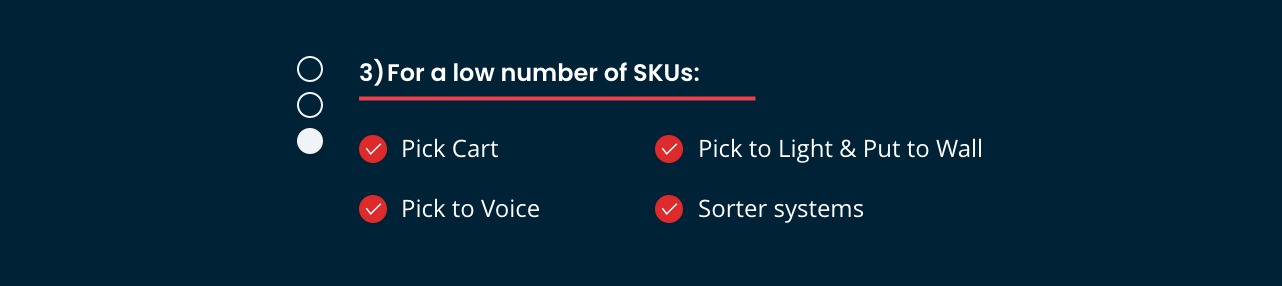

Pick to Light & Put to Wall

The Pick to Light and Put to Wall technology works based on a system of illuminated displays that indicate to the operator the exact quantity of products that must be supplied from each SKU to complete the preparation of an order.

When the orders are finished, the only thing that the operator has to do is confirm by means of a button, to be able to continue with the next one.

Profits

| Real time system | |

| Automatic inventory updates (indicating what needs to be refilled) | |

| Interconnectivity whith other automatisms | |

| 99.9% picking accurancy | |

| Easy adaptability to slotting changes | |

| Pick to Light Productivity: Up to 1,100 lines person/hour | |

| Put to Wall Productivity: Up to 600 lines person/hour |

.jpg)

Put to Light

Similar to Pick to Light, Put to Light is an order fulfillment system designed to visually guide personnel. In this, the luminous displays indicate to the operator the position to which he must go to complete each order.

With Put to Light, operators must confirm orders in all positions that required product, in order to continue with the next zone until the order consolidation is completed.

Profits

| Real time system | |

| Automatic inventory updates | |

| Interconectivity with other automatisms | |

| 99.9% picking accurancy | |

| Easy adaptability to slotting changes |

Pick to Voice

The Pick to Voice is a voice-guided order fulfillment system, in which the operator receives instructions on the quantity of products to be supplied through a bluetooth headband that has an integrated microphone.

Profits

| Inventory control in real time | |

| Increses in picking speed up to 10-15 | |

| Comfortable and ergonomic assortment by allowing the operator to have his hands free | |

| 99.9% picking accuracy | |

| Productivity: Up to 200 lines person / hour |

Pick Cart

The Pick Cart is a technology that works by means of a cart that contains several illuminated displays to indicate the quantity of pieces to be taken from each shelf in a specific position.

Here, the displays show where the products should be placed for each order, as well as the quantity to be supplied in the cart; so that the operator repeats this process until the orders are completed in the different areas.

Profits

| Simultaneous assortment of several orders | |

| Flexibility of adaptation to other technologies | |

| Maximum picking precision (99.9%) | |

| Productivity: Up to 300 lines person / hour |

Autonomous Mobile Robots (AMRs)

The mobile robots or AMRs are the result of the innovations of intralogistics 4.0, to automate the processes of assortment of the Distribution Centers. These robots are controlled by software that integrates artificial intelligence mechanisms, which gives them the ability to perform operations autonomously.

Likewise, these technologies operate under the “Good to Person” principle, which is why they are designed to bring the products to be supplied to the consolidation stations, so that the operator can prepare the order.

Thanks to this, AMRs have been especially useful for assortment in e-Commerce channels.

Beneficios

| Easy integration with Pick to Light, Put to Light technologies, among others | |

| High flexibility to scale the solution | |

| Maximum safety and ergonomics of operation | |

| Productivity: Up to 500 lines person / hour |

Mobile Robots 3D

Like AMRs, 3D mobile robots also have the ability to mobilize autonomously thanks to the intelligent software that controls them. However, their particularity is that they can move both horizontally and vertically when anchored to the storage racks.

Likewise, 3D mobile robots make it possible to take advantage of storage space in a much more productive way, since they also integrate a high-density vertical storage system. Being Good to Person solutions, they generate a completely agile and safe environment for operators, allowing order preparation in less than 5 minutes!

Profits

| Throughput and / or storage scalability without stopping the operation | |

| Storage density 5 times higher than traditional shelving systems | |

| Robots with a maximum load capacity of 30 kg. | |

| Productivity: Up to 600 lines person / hour |

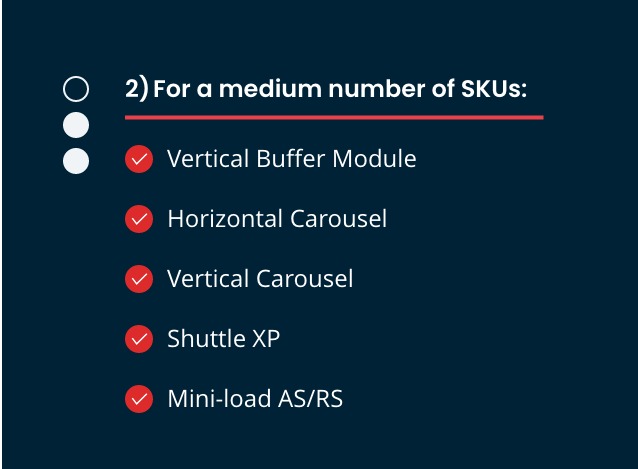

Shuttle XP

The Shuttle XP is an automated warehousing solution, ideal for applications that require medium to high throughput in distribution. They integrate different technologies, such as Pick to Light, barcode readers and software interfaces, to guarantee a maximum level of precision in the assortment.

Beneficios

| Savings of up to 85% of the useful storage area | |

| Modular design that allows it to adapt to any required height, both before and after installation | |

| Good to Person Solution | |

| Productivity: Up to 450 lines person / hour |

Vertical Buffer Module LR35

The Vertical Buffer Module LR35 is a highly efficient solution for the storage and assortment of products with light weight and small volume. It has features designed with maximum ergonomics in the picking stations, to simplify the order preparation process.

Its cargo containers support up to 35 kg. And integrate technologies such as barcode scanners and Pick to Light systems to increase the speed and precision of picking.

Beneficios

| Controlled access that guarantees the safety of stored products | |

| Maximum energy efficiency (consumes a third of the energy of comparable systems) | |

| Easy scalability thanks to its modular design | |

| Good To Person Solution | |

| Productivity: Up to 500 lines person / hour |

Vertical carousel

Vertical carousels serve to streamline the order picking process by providing quick and accurate access to stored products. These solutions are especially suitable for items with a high frequency of picking, since they bring the tray with the product that is required through the shortest possible path.

Profits

| Save up to 75% of storage space | |

| Productivity increases of up to 60% | |

| Maximum security of the stored merchandise | |

| Good To Person solution | |

| Productivity: Up to 450 lines person / hour |

Horizontal carousel

Horizontal carousels are ideal solutions for fulfillment operations with high recovery rates and medium to slow product flow. This system is supported by Pick to Light technologies to indicate the quantity of items to be supplied.

In this automated warehousing solution, items are stored compactly in a reduced space, eliminating unproductive picking routes in the warehouse.

Profits

| Allows you to handle all kinds of products | |

| Ergonomic design | |

| High flexibility thanks to its adaptive design | |

| Good To Person solution | |

| Productivity: Up to 450 lines person / hour |

The specialized item sorter is an exceptional technology for consolidating orders at high speeds. It is characterized by having a "loop" shape, as well as by the use of trays to move, classify and supply different types of products.

With this solution, the operator performs the picking process by placing the products on the trays, so that when the system detects ー through a barcode reader ー that a certain item is required to complete an order, it deposits automatically in your consolidation zone.

Beneficios

| Maximum safety when handling products | |

| Easy integration with Pick to Light technologies | |

| Ideal for irregularly shaped products | |

| Productivity: Up to 13,300 items / hour |

1) Pick to belt

The Pick to belt is a comprehensive solution for box order picking, encompassing various technologies such as radio frequency (RF) systems, Pick to Voice and different types of conveyors.

The design of this solution consists of the installation of a belt conveyor in the center of a designated area, where operators receive (through Pick to Voice systems) the instruction of which products should be placed on the conveyor for their respective assortment.

Subsequently, through radio frequency technologies, the system detects where each product should go to complement each order. Once the order is consolidated, a sorter sends it to your boarding area.

Profits

| Reduction of working hours | |

| Productivity increases of up to 200% | |

| Ergonomics | |

| Decrease in operating expenses |

Shoe sorter

The Shoe sorter is a widely used solution in multiple industries thanks to the fact that it allows classifications and assortment of products at high speeds.

This sorter is one of the most flexible sorting equipment on the market, as it can handle a wide variety of products weighing up to 40 kg. In addition, it allows to implement dual outputs (left and right), as well as versatile geometric arrangements.

Profits

| Aluminum design for optimal product glide | |

| Convenient maintenance | |

| Silent | |

| Throughput: Up to 400 products per minute | |

| Handling of various types of products |

.jpg)

Cross belt

The Cross belt is a high-end sorter for classifying and sorting products at high speeds. Unlike other sortation systems, the Cross belt allows you to handle products of various dimensions, weights, and depths without them suffering any kind of damage.

Likewise, it is a very versatile system that can be installed in a linear or “loop” shaped with bidirectional or unidirectional output arrangements.

Profits

| Maximum safety when handling products | |

| Ideal for products with different characteristics and / or amorphous typology | |

| Cost savings for space and operation | |

| Throughput: Up to 500 products per minute |

Narrow belt

The Narrow belt is distinguished by being a product sorting and assortment solution for medium flows..

This sorter can be configured with unidirectional and bidirectional arrangements according to the operational requirements of your DC, in addition to offering a higher output density per linear foot by providing the possibility of diverting the product at 30 ° or 90 °.

Profits

| Maximum ergonomics | |

| Silent | |

| Sorter with the best energy savings on the market | |

| Simple and inexpensive maintenance | |

| Throughput:Up to 120 boxes per minute |

Push sorter

The Push sorter allows to classify and sort products with different dimensions and characteristics. It is ideal for assortment operations with low flows and is one of the most used equipment in a wide variety of industries due to its ease of implementation and accessibility.

Profits

| Maximum safety when handling products | |

| Simple and inexpensive maintenance | |

| Throughput: Up to 45 boxes per minute |

Push-up Wheel

The Pop-up Wheel is a sorter used in order fulfillment applications that handle medium to high flows. The peculiarity of this equipment is that the units to be handled must have a flat and rigid base, so its use is ideal for cardboard boxes or plastic totes.

Its design is made up of a single band that intersperses different deviations to carry out order consolidation. It is a team with great flexibility to integrate various outputs according to the needs of your Distribution Center.

Profits

| Increase in assortment productivity | |

| Minimal maintenance required | |

| Versatility of outputs | |

| Throughput: Up to 80 boxes per minute |

The Mini-load AS / RS are automatic storage solutions, specifically designed to handle boxes or totes (containers with regular shape).

They are an excellent tool to support assortment operations that handle medium product flows, as they allow handling boxes or totes of up to 300 kg., Providing the ability to take up to two products simultaneously.

Beneficios

| Controlled access for maximum storage security | |

| Quiet performance | |

| Easy scalability | |

| Simple maintenance |

.jpg)

1) Unit-load AS/RS

The Unit-load AS / RS is a specialized equipment for the storage and assortment of pallets. It offers fast, smooth, and reliable performance thanks to its state-of-the-art design.

It can measure up to 40 m. high, easily adapting to the load and weight profile of your products, as well as to the construction dimensions and operating environment of your DC.

Profits

| High speed operation | |

| Adaptative design | |

| Safe operation for employees | |

| Forklift traffic reductions | |

| Simple maintenance |

2) AGVs (Automated Guided Vehicles)

AGVs are one of the main technologies that have replaced the use of forklifts for pallet assortment operations thanks to their great flexibility, in addition to considerable increases in productivity.

This solution is very versatile since it allows you to design and modify the trajectories of the vehicles according to the requirements of your operation. Over time, AGVs have evolved to a great extent, so in addition to being more reliable, they have become much more accessible.

Profits

| Greater safety for operators | |

| Possibility of operating 24/7 | |

| Versatility of applications and configurations | |

| Safety in handling products |

Before the emergence of the COVID-19 pandemic, e-commerce order preparation was distinguished from other distribution channels by its high level of demand in delivery times and the marked peaks in demand derived from different seasons of offers and promotions.

After COVID-19, we can see how these badges gained even more strength thanks to the exponential growth that electronic commerce has had during this time (+ 300% in Latin America according to Kantar).

However, all kinds of challenges have also been added to the above, such as:

![]() Unpredictable consumption patterns

Unpredictable consumption patterns

![]() Clients dispersed in different territories.

Clients dispersed in different territories.

![]() Reduced orders in product quantity with greater emphasis on delivery speed

Reduced orders in product quantity with greater emphasis on delivery speed

Given this, today more than ever the need to optimize the fulfillment processes of this challenging channel stands out, in order to meet customer expectations, improve their shopping experience and ensure a high level of competitiveness.

To carry out a project to optimize the assortment of orders for an e-commerce channel, it is first necessary to carry out an analysis of the specific needs of the company, taking into account its economic capacity together with other analytics related to its operation, the profile consumer, among others.

Once this analysis is completed, it is possible to define the type of technological infrastructure that will be required to be implemented within the Distribution Center; always bearing in mind that gradual automation can be incorporated to avoid strong undercapitalization.

To ensure a maximum degree of visibility and certainty in the order preparation process (and, in general, in the entire operation of a Distribution Center), intelligent control software is an indispensable tool.

Next, we explain the three types of software that you can implement within your DC.

1) WMS

Whether your Distribution Center is conventional, semi-automated or fully automated, the WMS (Warehouse Management System) is the elementary software to manage all the tasks that must be carried out daily within the DC.

Some of its most outstanding features consist of managing:

| Recipits of goods | |

| Organization and monitoring of activities carried out by staff | |

| Traceability of stocks | |

| Storage of products logically and precisely | |

| Order preparation process | |

| Shipment of goods | |

| Analysis of results and creation of reports |

2) WCS

The WCS (Warehouse Control System) is the software that allows to control all the operations sent by the WMS regarding the activity flows. This tool is in charge of “giving instructions” to the automatisms about the tasks that they must carry out, analyzing the fluidity and effectiveness of each one of them.

In addition, WCS helps to collect valuable data from the operation, to transmit it to the central management software, analyze it and provide a more accurate view of the performance of the DC.

Principal functions:

| Direct and maintain control of automation | |

| Task synchronization | |

| Real-time data collection | |

| Sending notifications in real time about possible problems related to the execution of activities |

It should be noted that, from the level of semi-automation, the implementation of the WCS becomes essential.

3) WES

The WES (Warehouse Execute System) facilitates the execution of tasks in environments with multiple automation and great complexity between processes. It is designed to interconnect each process, giving an immediate response to all automation equipment according to the necessary requirements.

With the passage of time, this software has evolved to the extent that, currently, it is no longer a simple execution program, but now allows combining WMS and WCS functionalities.

Most important functions:

| Process improvement | |

| Material flow management | |

| Execution and control of supplies | |

| Enrichment of the intelligent dynamics of the DC |

Each automation solution involves a series of alternatives that must be carefully analyzed, to define the one that presents both greater viability and greater tangible and intangible advantages for your DC.

Likewise, it is essential to forecast the life cycle or the capacity that the solution will have in the future, considering the growth projections of the Distribution Center.

Another important factor to consider is the financing method with which the investment will be made. Whichever mechanism you choose, don't forget to factor in capital inflation!

Finally, what would the automation project be if it did not have the advice of a supplier specialized in the development of this type of solution?

Make sure you have the support of a company highly experienced in intralogistics automation, whose reputation is proven in the market, and which in turn guarantees a robust local support that allows you to operate under the most demanding standards 365 days a year.

At G.I.Eicom, we want to be that ally that helps you guarantee an order preparation system capable of successfully responding to current and future market demands.

Hundreds of companies in LATAM and the southern US have verified our results!

You can be the next success story!

Contact

Tlalnepantla, Edo. de Mexico.

Our Locations

Edo de México

Querétaro | Guadalajara

Monterrey | Chihuahua