One of the main challenges for plant engineering managers is to find effective material handling solutions that allow them to: maintain timely control, ensure high-quality finished product delivery, and gain more space in their production plant.

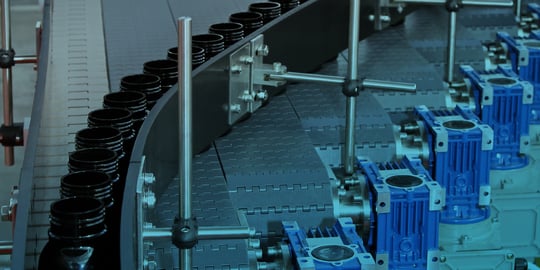

Focusing on the handling of finished product in industries such as Personal Care, where there are large flows of products, it is essential to have mechanisms such as conveyor systems, to move materials from the packaging area to the finished product warehouse, from a fast, safe and efficient way.

But how do I know which conveyor system is best suited to the finished product handling of my plant?

The selection of the ideal conveyor system will depend on a few key variables, such as:

● Product features: Dimensions, flow in units per hour, type of packaging, etc.

● Product behavior: Depending on the way of transfer (totes, boxes or shrink), a solution with bands, rollers, etc. is selected.

● System trajectory: According to your needs, they can be supported on the ceiling, at floor level, underground or aerial.

In this way, the first thing that must be analyzed is the type of product, the characteristics of the packaging, the production flow and the layout of the production plant. From these variables, the optimal mechanism to use can be determined.

In the case of the Personal Care industry, which involves high-volume production, different products and presentations that must be operated under strict corporate standards, an important challenge is that production never stops, in addition to avoiding losses due to mishandling or damage to the packaging.

For this, some of the conveyor subsystems that are normally used for the handling of finished products in this industry are lifting systems, since they have a variety of versatile applications ranging from vertical, reciprocating, continuous elevators, to spirals, according to your requirements.

Among these, the spiral elevators are the most frequently used in the production plants of Personal Care companies, because they are extremely useful to raise or lower product flows at a high rate, in a fluid and reliable way.

Likewise, box conveyors are also implemented which, for them, different variants are applied such as accumulation or transport conveyor systems; mergers, which allow you to join several lines into one; and classification systems or sorters.

Whatever your need, at G.I.Eicom we offer you the best conveyor solutions to optimize your handling of finished product and thus ensure that your plant complies with its deliveries in a timely manner, and without any type of waste.

With more than 35 years of experience, we are the leading company in the creation and implementation of turnkey solutions to systematize and automate product flows.

Committed to your return on investment, we guarantee that our systems offer you the best cost-benefit ratio according to your needs. Contact us!