When we think of an automated warehouse, we refer to those key tools that allow significant solutions for the optimization of spaces, and the protection of the product, thus helping the agility and precision of the operation.

In this blog we talk about the different automated warehouses that exist, and how you can

choose the right one according to the industry and density of your operation.

How do you know what type of automated warehouse is for you?

Yes, although there are various types of automated warehouse, not all of them can help you make the operation more efficient. The choice has everything to do with the following characteristics:

- The level of operational dynamism you need.

- The scalability you expect for your Distribution Center.

- The product you work with.

Benefits of integrating an automated warehouse in your Distribution Center.

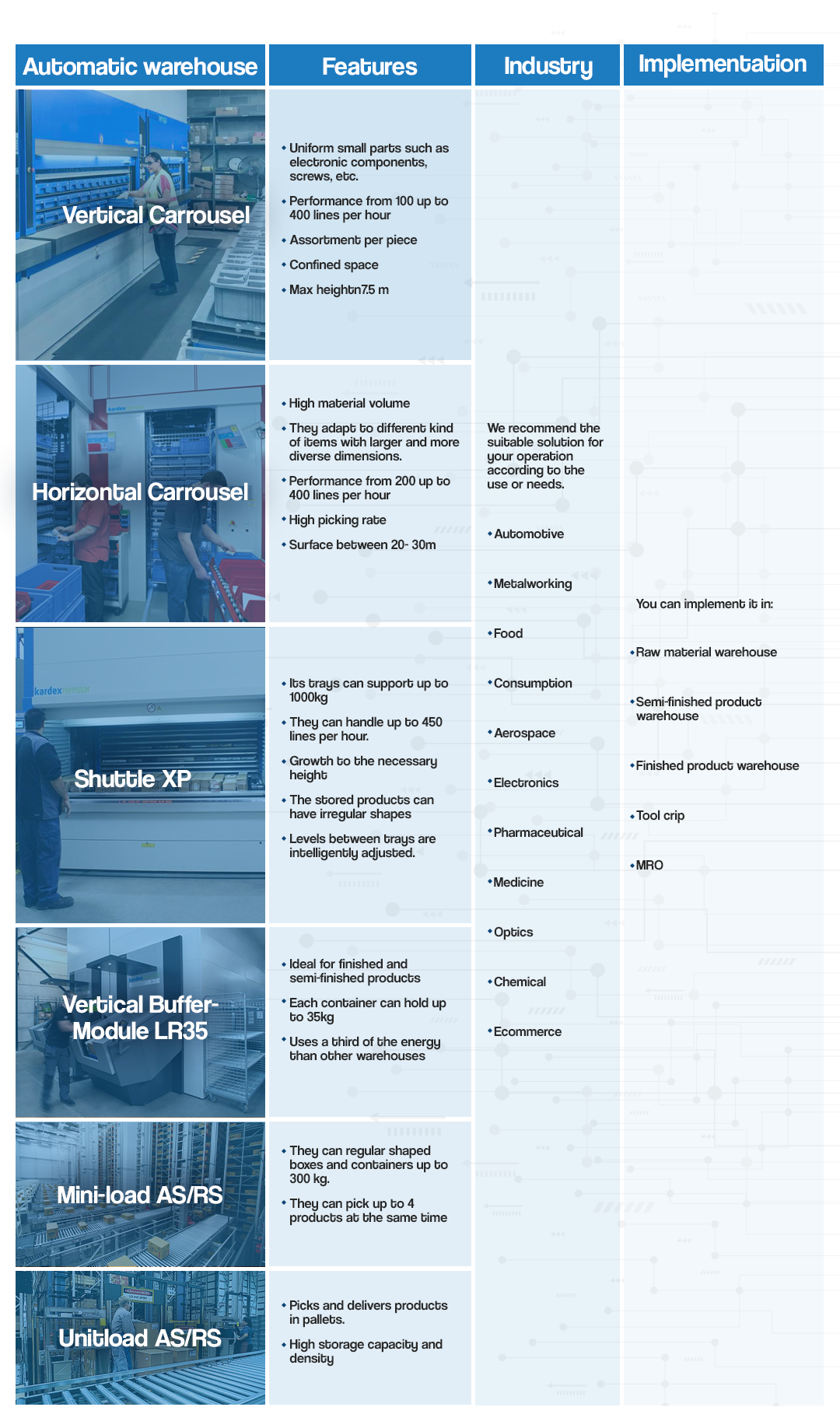

Let´s see the classification in the following table, it can help you with much more precision:

If you are considering integrate an automated warehouse, we advise you to analyze the following relevant aspects:

- Personalized analysis and advice. Your supplier must carry out a detailed analysis of the current operation, in order to have more certainty and success in the proposal and integration of the automated warehouse.

- Support / infrastructure. It must offer you a plan that includes various stages in coordination with you, thus ensuring compliance with the agreed success criteria, in addition to providing complete training to the operators.