As we well know, the automotive industry is one of the sectors that most demands highly detailed material handling operations. It is even estimated that between 30 and 85% of the costs that arise when entering a product into the market are related to the handling of materials.

According to the National Auto Parts Industry (INA), it is estimated that the production value of this sector will be 112, 702 million dollars during 2023.

It should be noted that in the auto parts industry, quality is the neuralgic point of the operation since it must be ensured that the margin of error and defects is eliminated.

Keep reading as we will share valuable tips for handling materials in the auto parts industry.

Risks in material handling

Having materials handling aligned to quality standards guarantees us innovative, safe, and highly functional processes, which translates into customer satisfaction and the reputation of your company.

To begin, it is necessary that you identify the possible failures that may arise. According to a survey of heads of security and production areas, these are the most common risks in the

industry:

● 72% of interruptions in the supply chain process.

● 72% of the operation is affected by errors or failures in the operating equipment.

Design competitive material handling for the auto parts industry

To counteract this effect, we are going to share three useful tips.

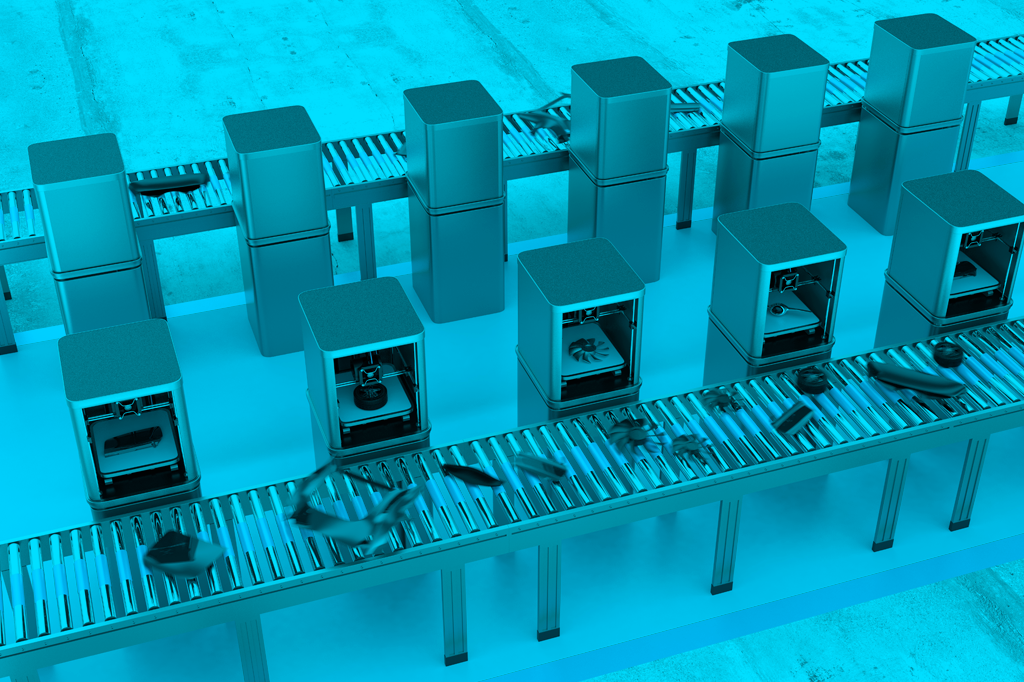

1.- Make technology your ally. The fact that you can automate processes with the help of technology to benefit your operation could represent the stagnation or growth of your company. Currently there are multiple technologies for material handling that will help you maximize results, some of them are:

● Automatic warehouses (AS/RS)

● Vertical and horizontal carousels

● Shuttle

● Miniloads

● Conveyors

●Software

2.- Ensures correct implementation. We will talk of one of the problems that most companies experience: traceability. Remember that integrating technology is of little use without a comprehensive design that ensures the correct flow of technology working together.

At G.I.Eicom we carry out a thorough analysis of the particular problems of material handling in your auto parts industry, to offer you a solution that allows you to have optimal inventories and to ensure an assortment without errors, reducing occupied areas by up to 60%, in addition , of the tracking of the operation.

3.- Quality control is essential. We recommend that you integrate quality control into your material handling, from start to finish, which will help you have certainty with your customers, and healthy operations.

Remember that the auto parts industry requires suppliers with a high level of specialization and care, not ensuring these premises could bring you serious problems, even legal!

Do you want a diagnosis of your material handling? Leave us your information, a specialist will contact you.