Discover why these systems help you grow your business and the importance of implementing them.

Discover why these systems help you grow your business and the importance of implementing them.

Material handling operations are split into 4 main items:

- Bulk products handling.

- Bottles or finished products handling.

- Boxes handling (logistic management).

- Pallets handling (logistic management).

Every material has diverse features and need a conveyor system that helps them handling and distributing through different areas.

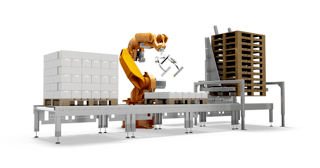

In previous articles, we were talking about conveyor systems for boxes handling, this time we will tell you why conveyor systems for handling pallets are so important. Let’s start:

Productivity: A pallet conveyor system tell us about a dedicated and standardized operation, which allows the productivity of your company to rise and costs to be reduced. This is because the operation is much cheaper than with conventional forklifts. A pallet conveyor system allows accumulation zones to ensure greater output flow capacity.

Cleanliness and tidiness: The flows are tidied, since they correspond to a logical handling and not to movements liable to the will of operators. They provide tidiness and an institutional environment by allowing facilities to generate a clean and harmonic environment.

Speed: It is priority that the operation is carried out with conveyors that allow the platform to move quickly and accurately to the storage area or to the loading area. This will help reduce crises and downtime operations. Remember that these issues could severely affect the deliveries you have agreed to.

Decreasing accident risks: Due to the dependence of personnel, who often make mistakes or do not comply with regulations, the use of conveyors provides minimum risks compared to traditional forklifts.

Displacement: A strategically implemented conveyor system will prevent inactivity of the product. After the material crosses the production lines, it is common that piles of pallets are formed, creating conflicts of internal movements. The problems are that after having large piles of pallets, it is difficult to move, and reduce the workspace

Pallet conveyors organize and put the pallets in the ideal point to wrap them, later they allow their delivery in the point of loading for store or distribution to truck.

When these operations have low flows, the use of a pallet kack is common. But when flows are important, it is necessary to implement a system of pallet conveyors that provide continuous movement to the operation.

Modularity: Pallet transporters allow modularity, as they are built like a mechano. The modularity is about conveyors adaptability to the requirements of the customer, the work area, the weights managed, the type of platform, etc.

Do not lose the trust of your customers for an out of time delivery, a product mismanagement or inefficiency of your work tools. Contact us and we will show you all the advantages that a pallet conveyor brings to your operations.