The essence of the Distribution Center (DC) is to make more efficient, effective, economic and transparent for all supply chain operations. There are several innovative solutions that all Distribution Center should contain; especially by the constant changing that suffer temporalities, emergencies, the market in general. Now they are required orders smaller of smaller quantities but more orders, even more personalized.

The essence of the Distribution Center (DC) is to make more efficient, effective, economic and transparent for all supply chain operations. There are several innovative solutions that all Distribution Center should contain; especially by the constant changing that suffer temporalities, emergencies, the market in general. Now they are required orders smaller of smaller quantities but more orders, even more personalized.

Here we present 3 innovative solutions used in different areas:

1.- Receiving area

When the products arrive at the distribution center, it does not always has the equipment and personnel to receive them, which discourages high inventory download flexibly and optimally.

The boxed product unload may take too long, making this process is not only ineffective, but also the entire DC operation. The telescopic conveyors are motorized technology, although it has many years of development, they are just being integrated into modern centers of Latin America.

This tool is an automatic reception system able to enter directly into the truck or leave it to the loading dock; while the cases are scanned with the products and records input or output of stock.

For the download pallet, we also have an innovative solution: the AGVs. These vehicles enter the truck to load or unload, recording the inputs or outputs. They have a camera that has a built-reading system at the bottom, which reads the bar code of the product; in addition to optical systems that can download or upload autonomously.

Both telescopic motorized equipment and AGVs avoid personal injuries and errors in high stocks, resulting in speediness and productivity.

Both solutions are directed under a WCS software module, making that stock record is provided in real time and automatically.

2.- Stock area

In the stock area, according to your particular type of operation, we can choose a Pick to Light, Pick to Voice or Pick to Belt system, combined with an automatic classifier.

In the Pick to Light we can count on conveyors, or without them. It is a system with different types of equipment, such of them are the conveyors and carousels and software guided displays. The Pick to Voice features audio headsets, which are carried by operators who follow automatic verbal instructions from software which commands them. In the Pick to Belt operators receive manual or automatic orders for placing products on a band that takes care of transferring and automatically classify them according to the proper criteria.

A very important advantage is that it is a technical system that eliminates errors, paperwork, decision making and productivity. WCS module also records the waves of the stock, classifying them according to the rules of business.

3.- Dockside

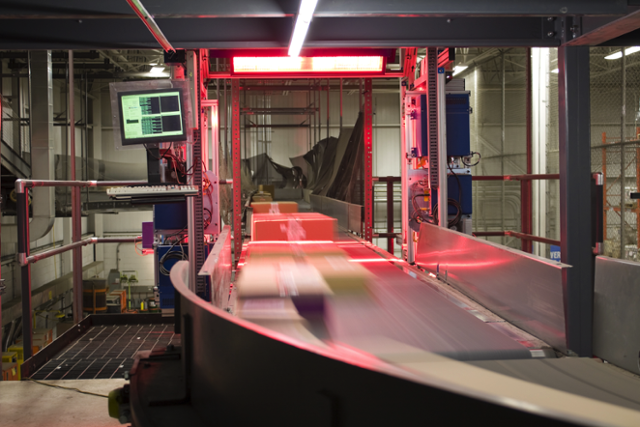

Once your products are machined on the band of the chosen system of order fulfillment, they are driven into the sorting area or sortation. In this section there are several sorters that meet the needs and characteristics of your products.

An innovative solution acts implementing a system that allows the flow of products goes directly to the truck, all being automated. Each classification may be made as the client demands, whether by route, consolidated, by order or request. It is a great advantage that saves a lot of time and prevents errors in your shipment (they not enter more or less products, they are no errors on route and accidents are avoided).

GIEICOM mission focuses mainly on finding the best alternative to more productive processes of your company and ensure that it has a solid structure to face market challenges.

If you want to create innovative high performance systems, request a free consultation with a professional of GIEICOM, he will work in coordination with you.