Carefully implements and supervises is vital for a company’s end-of-line processes, which will ensure the success of operations in its production plant.

Among the areas to which intensive care should be take, are the following:

Conveyor systems and mergers

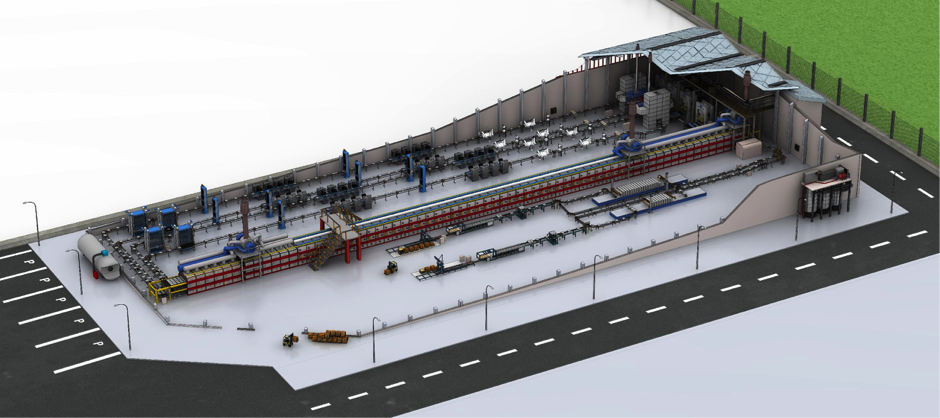

Once you have the product in carton boxes, is crucial to transport it through a conveyor system. Normally these conveyors lines converge the flows from many to few lines, to take the products to a previous classification area before reserve or to the loading dock.

Sortation system

The conveyor lines are classified at the end of the process by sorters, which are automatic equipments that from the barcode reading of the product achieve a fast and efficient distribution to the different destinations (diverts) required by the operation.

Palletizing

Another indispensable product in the end of line area is palletizing.

This process is selected according to the capacity handled in the lines, it can be conventional palletizing (35 boxes per minute), or robotic palletizing (from 2 to 4 lines simultaneously). Choosing between one and the other will depend on the flow handled after receiving the product from the sortation system.

Once palletized, it is transported to warehousing by forklifts or AGV's.

Storage area

When the product reaches the storage area, it can be stored by conventional racks and selective racks, or trans-elevator AS/RS rack.

Trans-elevator AS/RS racks are automatic systems with robots, which allow high storage capacity with high flow and inventory control (13 levels of height and up to a height of 40 meters).

One of the advantages of automatic warehouses is that they are customized designs, and they are selected according to the product batch, product type or the special conditions required.

Do not forget that to achieve an effective intralogistics design, it is essential to have a WMS. This management system helps to monitor positions, expirations, batches of products and countless variables that ensure the success of the industrial process.

Staying with old operations methods, can cost you even the same permanence of your business. Remember, the more automated your workplace, you generate greater certainty and greater capacity and business competitiveness.

If you need specialized advisory, do not hesitate in contact us. For us, your workflow and business growth is a priority. Call us!