We previously shared a blog where we give you the context of the meaning of Industry 4.0 and the scope it represents for intralogistics automation processes. Today we will examine a little bit more some applications of Industry 4.0 and the areas in which it will influence within the current industries.

We previously shared a blog where we give you the context of the meaning of Industry 4.0 and the scope it represents for intralogistics automation processes. Today we will examine a little bit more some applications of Industry 4.0 and the areas in which it will influence within the current industries.

Collaborative Robot, leader in intralogistics automation

Collaborative robots are ideal for order assortment. This technology is very efficient for carrying out activities that are repetitive for operators, as well as to make tasks in which they must travel long distances a lot easier, which saves a lot of time to the general workforce.

Collaborative robots can also help with inventory counts, the assortment of products, product assortment in pallets, assortment of products in boxes. Even, within the Distribution Center they potentially help with e-commerce operations.

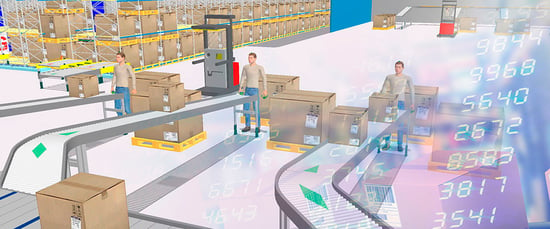

Virtual reality, ally of intralogistics automation

Virtual and/or augmented reality, recreates a reality in which you can live with scenarios that do not exist, but could be implemented and bring improvements to companies.

For example, they help intralogistics training processes. That is, thanks to virtual reality, employees can verify and learn from the maintenance of sortation, assortment of orders or the operation of automatic warehouses. This functionality allows you to reach more employees, without the need to invest in a specialized department, or extra staff to train your industry.

Augmented reality also works successfully as a real-time assistant. For example, you can immediately attend a person who is miles away, without having an operator to visit the physical point. This allows greater autonomy, save time, energy, and money and above all, does not stop the operations of your clients.

Additionally, virtual reality allows intralogistics automation companies to simulate scenarios that will help them know the impact that their decisions will have beforehand, without the need to invest insecurely.

To go deeper, virtual reality allows companies to assertively analyze issues related to obstacles in processes, operations, implementations, etc. before making a high investment without the certainty of a medium or long term ROI.

Would you like a specialized advice for intralogistics automation processes that you could implement in your industry and improve your operation? Contact us; we have the best leading edge industrial technology!