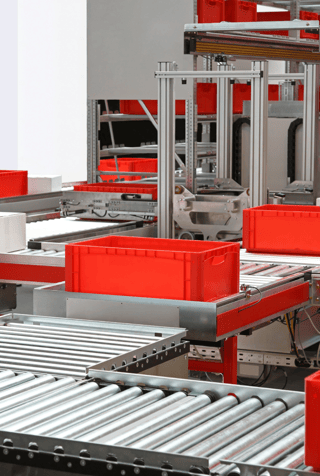

The different kinds of conveyors that integrate the system are intended to increase operation’s productivity based on the implemented configuration. When we talk about conveyors system for boxes’ handling, we are also talking about equipment that is attached as modular tools.

The different kinds of conveyors that integrate the system are intended to increase operation’s productivity based on the implemented configuration. When we talk about conveyors system for boxes’ handling, we are also talking about equipment that is attached as modular tools.

There is a variety of equipment that can be implemented according to production plants or distribution centers’ requirements. We will describe the most common tools based on operation needs:

RB and SB conveyors

When the product has to be accommodated, lifted and transported, roller or slider beds conveyors are used. The roller bed or RB dramatically reduces energy consumption because they have low-power motors; these are perfect for moving heavy boxes; however, in the case of light loads, a slide bed or SB is more cost-effective.

Gravity conveyors

These are non-motorized equipment that can either use a slight angle for moving or accumulating products with hard and flat bottom or be fully horizontal for driving products between different places. Usually, they are used at the beginning or at the end of the process where accumulation is needed; they are even a great option for low pressure or no-pressure accumulations, making processes a lot easier.

Accumulation equipment

These conveyors within an integral electric, electro-pneumatic or mechanical system that controls the moving pressure in order to avoid products to crashing against each other or accumulate them with the minimum pressure, when needed.

Continuous and reciprocating lifts

Continuous lift can manage high flows of products (around 200 boxes per minute). They can be either belt or chain vertical conveyors for a continuous spiral lifting.

Continuous lift can manage high flows of products (around 200 boxes per minute). They can be either belt or chain vertical conveyors for a continuous spiral lifting.

On the other hand, reciprocating lift go up and down a few times per minute; even when they can manage high weights such as pallets with up to three tons, they operation is similar to an elevator with less security requirements.

Induction conveyor

This equipment moves and gathers high flows of boxes and packages into a single and faster conveyor. There are lot kinds according to the type and flow of products. These can combine flows of up to 200 boxes or packages per minute.

Sorters

This equipment is specifically design for classify high flows of products, based on the required criteria. The sorting can be made by orders, product’s type, areas, sizes, etc.

Control and software

These are all the electrical elements, hardware and programs to link the system with the client’s servers in order to obtain all its benefits. The appropriate implementation of this system results in a powerful tool of competitiveness, productivity, certainty and institutionalization for Companies.

Having a design and implementation of technologies that are not forefront and competitive means nothing else but a step backwards. In GIEICOM, our most important goal is to provide suitable tools to automate your facilities and therefore, increase your business scope and getting a better position in the global market. Call us now to discuss your Company’s future!