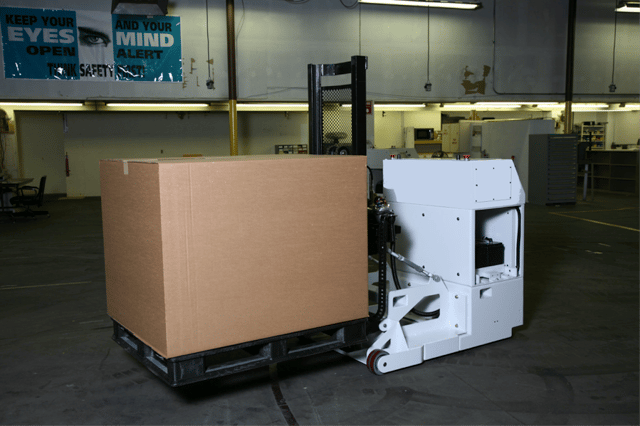

The AGV (laser) and AGC (magnetic guidance tape) are automated guided vehicles that are used in assembly lines as well as supplying materials to production lines and as transportation between different automated systems.

They are controlled by software in order to eliminate the need of being monitored or controlled by operators. They are completely self-sufficient.

Benefits and functioning of each one is following detailed so you can decide if this is the tool that your business is looking for.

1.- AGC

It is commonly used in assembly lines. This system allows to easily making changes through software and magnetic guidance tapes unlike conventional systems that can take several weeks before changing the process.

It works thanks to a floor magnetic tape and a reader within the vehicle that receives the information for guiding the route. It is used for assembly lines with fixed routes.

In order to identify its location, RFID transponders are place underground and these are automatically located thanks to signals transmitted to the software.

2.- AGV

On the other and, the AGV uses coordinates and reflectors.

It is always notifying its location to the system through visual lasers that look for 3 different surrounding reflectors, when these are reached by the laser, it will mean that the AGV is moving within the circle between such points.

The AGV is perfect for assembly lines’ refill due to the implied savings in different aspects that distinguished it from other conventional methods. In addition, it offers a more versatile operation, including the possibility of loading or unloading trucks.

Which their advantages are?

- Do not need major fixed installations.

- Offer flexibility and adaptability to assembly lines for future system’s improvements.

- Avoid stopping the line which results in important budget savings.

- Help to supply materials and parts to assembly lines, as well as supplying specific materials and automating parts’ supply. They also help to move the equipment closer just when it is needed (crystals, metals, screws, etc.).

- Work 24/7.

- Any change can be done right away without the need of spending weeks in repairs and modifications as conventional systems.

- Efficient management of traffic control.

- They automatically charged themselves when battery if low. There are even some AGV that can be charged just by passing by certain points along the plant.

Technology is constantly developing intra-logistics solutions that result in higher productivity and sophistication rates regarding operation’s management. GIEICOM provides the latest technology.

Let us know your concerns and operative problems. We can work side-by-side so you can be the best business of your market. Call us today.