One of the main elements in the conveyor systems design within the distribution centers, is the flexibility the system brings for future adjustments in the processes, because it is very typical that these are modified during time due to customer requirements. Many times these equipments are used for material handling or as a complement to order assortment or fulfillment activities.

Having such an important task in the intralogistic process, is necessary to find the best practices to optimize the transport or the processes in the DC. This is why in this blog we will talk about a subsystem that is very recurrent that is used within the "elevation systems" designs that often provide a friendly solution to the processes of material handling and thus achieve the order and efficiency you're looking for.

Elevator systems allows you to distribute your products at high speeds with a lower energy expense, as well as guaranteeing free space in the areas. In this way, you take the product as tidy as possible, and faster than at floor level, which brings you to have space available for feeding the intralogistic processes.

Compared to conventional systems, elevator systems allow you to streamline through small layouts.

Despite the benefits that elevator systems can give to your company, it is necessary to take into account the flow of products that you will have to be able to choose the lift system that covers in the best way your necessities.

- Reciprocating elevator. It only has one platform and allows you to drive from two to three boxes per minute, according to the height you

- Continuous elevator. This elevator allows you to handle up to 24 boxes per minute, ideal when you have a high flow rate of products. They only allow you to handle boxes or

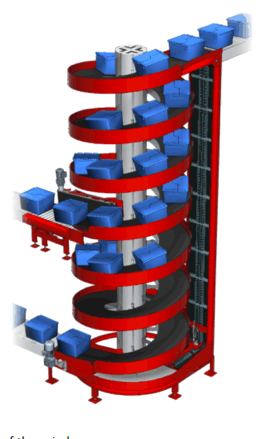

- Vertical spirals. This type of spiral allows you to handle a flow 100% continuous, depending on the configuration you are going to have. It also has many slopes so the configurations you can do in this system are

It’s important to consider the industry you are, the regulations that you have to follow, the flow you drive, the loading and unloading configuration that is required and the feeding of the elevator and discharge of it, to be able to choose the best equipment to ensure the desired productivity.

At G.I.Eicom we have the best solutions for your worries, do not wait any longer and come closer with one of our experts in intralogistics in order that you can solve your doubts. Contact us!