At GIEICOM, we know what an industrial investment means that is why we pay particular attention to providing the best solutions that generate a logistic and productive turn to our clients’ operations.

Our commitment starts with an operations’ analysis, after that comes the implementations of the suitable solution and later the after-sales service. In this way, we assure 100% of effectiveness in our work.

We want to share with you the following successful case of assortment system’s implementation so you can realize how productivity increase due to this automated solution:

What the problem was?

In 2015, a client who manufactures snacks had severe problems because his workers were constantly mixing up the products.

The products of this company were very similar, and for that reason, at some point, these seemed the same for workers. There were plenty of mistakes in assortment and returns, a lot of missing products, inventory problem, and unawareness of progress among other things..

What the solution was?

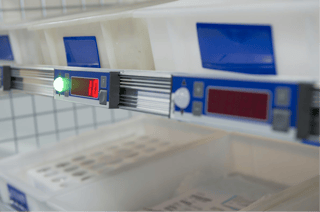

After 14 days of operation analysis and many work meetings between the client and our representatives; GIEICOM decided to improve the process by means of an even accommodation and pre-establish routes for products’ assortment, based on Carton Flow and Pick to Light.

There were 360 locations of Pick to Light, divides in 14 assortment stations. As a result, only 4 operators are now able to run the assortment process for the entire operation.

The overall process is as follows: the operators scanned the order, then the locations that had to be assorted were lighted up. Once they identify the lights, they went towards each location and take the quantity indicated in the display. Finally, they press the confirmation button in order to update the inventory in real time.

One of the benefits was having different indicating lights because many operators were able to work in the same area simultaneously, which results in a productivity increase.

What did the client obtain?

The company reported 99% of effectiveness in products’ assortment. Mix up and errors were eliminated. The assortment timing decrease one third of the time it took before. The total operative cost of each order was also reduced 25% and the clients’ satisfaction index went finally up to 100%.

The company reported 99% of effectiveness in products’ assortment. Mix up and errors were eliminated. The assortment timing decrease one third of the time it took before. The total operative cost of each order was also reduced 25% and the clients’ satisfaction index went finally up to 100%.

Currently, this client is provided with after sales service and a 24h/365 days coverage policy.

You could be our next successful case!

At GIEICOM, we pay special attention so our implementations create certainty, productivity and business competitiveness.

Share your problems with us and together we will take your company to the next level.