Pressure on companies for delivering products timely and correctly is going up. Currently, is very common to see companies implementing automated solutions in order to face this demand.

At GIEICOM, we know that running your successful business is not easy; therefore, we have created the following guide that contains the most effective and ultimate solutions for automating your distribution center:

1.-Pick to light: it is an order assortment system guided by lighting. The quantity of items to assorted is indicated by means of lighting displays.

2.-Sortation System: it executes processes such as: assorting, classification or cross-dock through sorters. These mechanisms are guided by a software and electronic controls that allow a quick, accurate and controlled sorting of different types of products.

3.-Pick to Voice: it is a hardware-software system that allows operators to carry out the orders’ assortment process through voice commands generated by the system itself which also receives oral feedback.

4.-Shuttle VLM: it is an internal racks’ accommodation made by an accurate robot which place or delivers orders as requested.

5.-Horizontal/Vertical Carrousels: these are automated solutions designed for assorting orders and manage inventories automatically. They increase productivity up to 600%.

6.- AGV System: these are automated solutions that move products either by dragging (small train-like device) or pulling specific structures that support such products. They can also work as forklift by carrying the products upon them.

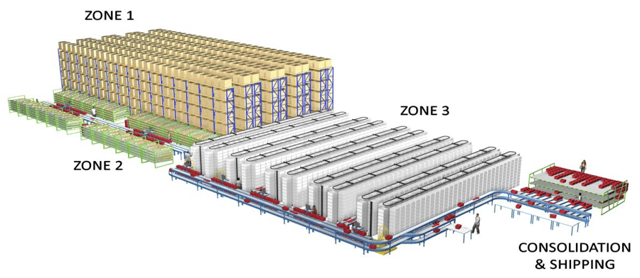

7.- Stacker crane, Miniload and Multishuttle: these are automated systems that deliver products within a warehouse; either in process, production or assembling plants or distribution centers. These are constituted by cranes high-precision robots that can travel long distances or heights in order to provide high density and storage capacity.

8.- Conveying System: this system consists of handling products at production areas or distribution centers by means of different types of conveyors. Products are received from different production lines and they are integrated within one main line to be transported, classified and sorted to specific areas of finished products’ warehouse.

9.- Loading and Unloading System: This is one of the best solutions for loading and shipping areas. These systems consist of a retractile conveyor either of motorized belts or motorized or gravity rollers or skate wheels.

If you want to know about each automated solutions, their benefits and operation systems, do not wait any longer and download now our free e-book with the best automation solutions for distribution centers. This information can improve your operations’ productivity immediately.