If you work with assembly lines, you know that you have to be competitive in the face of the current demand in production in Mexico nowadays.

An effective way to achieve this scalability is through the use of modular technologies, which allow product assembly operations to be quickly adapted and expanded. Here we will talk to you about 3 very important ones that you should evaluate.

What modular technologies do we recommend integrating into your assembly line?

One of the advantages of using modular technologies on assembly lines is the possibility of scaling production quickly and efficiently. If demand for a product suddenly increases, additional modules can be added to expand production capacity without requiring significant changes to existing assembly lines. This allows companies to quickly adapt to market fluctuations and take advantage of expansion opportunities.

Modular technologies allow for greater quality control. Each module can be manufactured and tested individually before being assembled. Let´s get to know more about them.

Pick to Light system. This tool is ideal for integrating precision, productivity and visibility benefits. The Pick to Light system works together in real time for inventory management, through the EXE Pick WCS Software Module in communication with the company´s WMS or ERP, thus the order travels to the different stations until it is completed.

Let´s look at the process in more detail:

- The operator scans the code of an order which activates the lights on the displays.

- Each SKU has a bright display that indicates the quantity of products to be supplied.

- The digital displays clearly indicate the quantity of the product to be placed.

- Once the correct assortment is placed, the order is confirmed and continues with the next.

Within the assembly lines, the Pick to Light system helps maintain good handling and assortment of assembly parts for dense production or different products.

Among the most notable advantages of technology we can mention:

- Better organization of SKUs or assembly parts, with aligned technologies.

- Use of the gold zone.

- An effective process is achieved: simple and aligned.

- Management of SKUs or assembly parts, with appropriate technologies.

The Pick to Light system gives the opportunity for modular scalability, since displays can be progressively added to strengthen production and scope, according to the demand that is acquired.

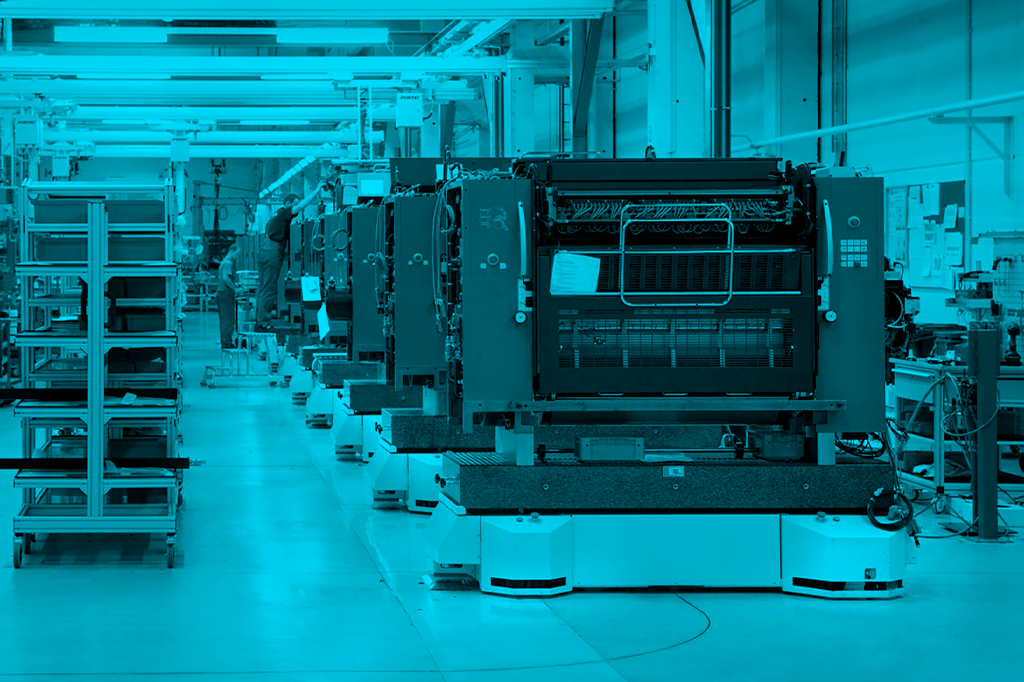

AGV´s Systems. When we talk about AGVs we are referring to automatically guided vehicles. AGV systems were introduced in 1954, by the Barret Electronic company of Northbrook, Illinois, U.S.A., which had the need to design a tow vehicle guided by a cable located on the ground for a food company. However, they have had great evolution and greater value today, their system is designed to optimize and offer efficiency in the flows of materials that involve assembly lines.

Even today, there are special adaptations according to Mordor Intelligence, in 2021 the warehouse freezer AGV was launched, which can operate from -23° C to 43° C, can also load up to 113.39 kg and has a hydraulic mast of 3 stages with integrated side shift and tilt.

Companies with high production volumes, such as Audi, use automation systems in their modular assembly line, through AGV´s equipment for the supply of materials, since its “good to person” principle optimizes flows and paths.

AGV systems offer enormous advantages, particularly in assembly and distribution lines according to their versatility, for example: hundreds of automotive companies use them as a basic element to assemble their parts and/or units in process at different stations. that are finished and are transferred by the same AGVs to the finished product warehouse.

Some of the most relevant advantages that AGV systems provide are:

- Reduction of operating costs

- Safety for staff

- Adaptability and optimization of space

Automatic storage. Automated storage and retrieval systems (AS/RS) allow high density for product storage through maximization of the use of height in reduced “footprint” areas. Automatic warehouses can be supported by Software to help in the management of manufacturing processes in matters of classification and management of parts or materials, avoiding loss during the process.

An automatic warehouse is a technology that focuses on saving space, as it allows companies to make better use of the area. Its automation converges to track each of the products and movements effectively.

Where to start integration on assembly lines?

One of the greatest benefits of assembly lines with modular technologies is the ability to produce a wide variety of products in a single system. Previously, companies had to invest in separate production systems for each type of product, which increased the costs and complexity of the process. With modular technologies, companies can save time and money by using a single system to produce multiple products.

Assembly lines maintain an important boom in various industries such as household appliances and automotive. Even the automotive industry in Mexico projects beneficial results, in 2022 it achieved an increase of 9.2% in its production of light vehicles, this results in an achievement of 3 million 308,346 units.

Do you need to scale your assembly lines with modular solutions? Let´s identify your real needs and design solutions according to your requirements that provide you with flexibility, support and savings. Tell us about your project! At G.I.Eicom we have more than 38 years guiding the market with cutting-edge technology and solutions.