Having an efficient distribution center requires a previous work. Even considering all cautions, you can have unexpected problems anytime.

In this article, we will talk about AGV and how specific problems can be solved. Analyze this information and confirm if the automatic vehicles are the ideal equipment to solve all the operational problems of your business.

Which are the main problems?

- High traffic of forklifts turn the space into a high risk area

- Accidents in the intersection points

- High cost of common forklift maintenance

- Difficulty to find expert operators to manage forklifts

- Waste of furniture

- Dereliction of product

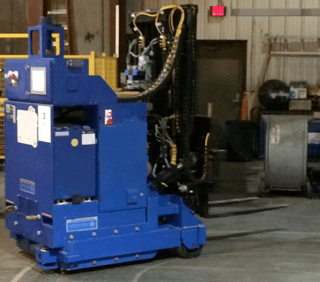

The best automatic solution that does not need any change in its infrastructure is the implementation of AGVs.

How to choose the best AGV?

To choose the best AGV for your business you have to analyze different aspects, such as: capacity, kind of operation, halls’ size in your distribution center, kind of product for transporting, number of trip per unit of time, weight and size of products and more.

The companies usually choose the fork lift AGV because its use is similar to a common forklift but with the advantage of having an automatic system.

In order to decide how many AGVs you need for your processes, you must pay attention to the intersection points, the kind of operation, when to charge the battery, if it requires a manual charger or a charging station. Once you decide how many AGVs you need, you will define which accessories you can install. Some of the special accessories are bar-code readers, cameras, and specialized smart software, among others.

It is also very important to have solid support after the warranty period, replacement parts, maintenance and updates.

Working together with GIEICOM will guarantee you the best automatic solutions according to your operations and kind of business. Fill in this form and our experts will contact you as soon as possible.